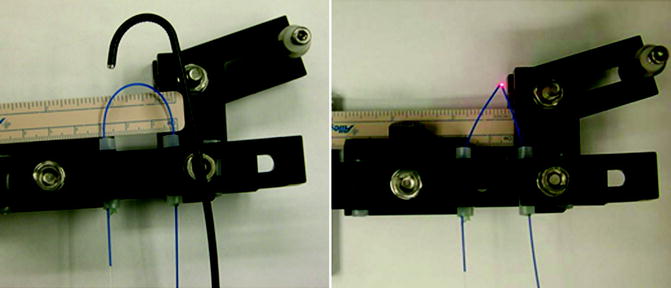

Fig. 14.1

High incidence angles cause by bending of the light

Flexible Ureteroscope Design: Impact on Fiber Performance

Flexible ureteroscopes are capable of high degrees of both primary and secondary deflection. These small caliber flexible scopes are capable of reaching stones in the lower pole of the kidney where shockwave lithotripsy is less effective [10]. However lower pole access has correlated with the need for ureteroscope repair, which can be a very costly endeavor with repair costs as high as $10,000 per incident [11]. Laser fiber failure with the scope deflected in the lower pole may also be contributing to scope failure. Therefore it is critical that laser optical fibers used for laser lithotripsy are able to withstand that sharp bends that are required to reach stones in difficult locations such as the lower pole of the kidney (Fig. 14.2).

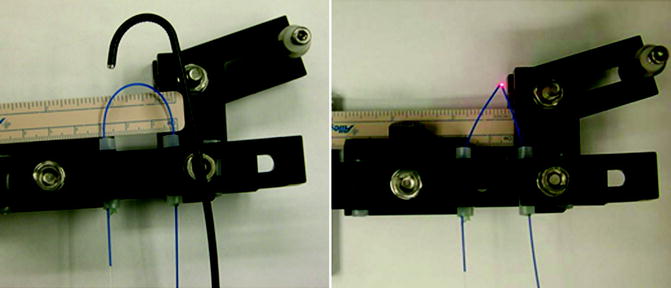

Fig. 14.2

Fiber failure during testing when the laser was activated

Fiber Evaluation

During lower pole laser lithotripsy of renal stones it was identified by the author that fibers were periodically failing when highly deflected and the laser was activated. However the failure was sporadic and appeared to vary highly from fiber to fiber. What could be safely treated during one procedure may result in fiber fracture and ureteroscope damage in another procedure. Therefore a set of objective tests were created in an effort to safely test the performance characteristics of a series of commercially available holmium:YAG optical laser fibers.

Fiber Resistance to Fracture with Bending

A series of 24 commercially available holmium:YAG laser optical fibers were evaluated with core sizes ranging from 150 to 365 μm. Fibers were placed underwater in a testing apparatus that created 180° bends. The bend radius was set at 1.25 cm and the holmium:YAG laser was activated at a pulse energy setting of 1.2 J at a frequency of 10 Hz for 1 min or until fiber failure. If the fiber did not fail, the bend radius was decrease by 0.25 cm and the testing repeated. The continued until the bend radius reach 0.5 cm or until fiber failure. The results demonstrated that there was a wide range of failure thresholds for the fibers tested. The worst performing fiber was the AccuFlex 200 (Boston Scientific, Natick, MA), which failed at a bend diameter of 1.75 cm. The InnovaQuartz LLF273, Convergent OptiLITI SMH1020F, and Dornier Lightguide Super 270 had the best performance by not fracturing even at the tightest bend tested [12].

Fiber Diameter

Fibers used for laser lithotripsy can be broadly classified into four categories based on the core-size of the fiber: (i) ≤272 μm, (ii) 365 μm, (iii) 550 μm, and (iv) 1,000 μm. For flexible ureteroscopy, fibers with core sizes ≤365 μm are used. The fiber core size however does not accurately represent what the total diameter of the fiber is. The total diameter is the summation of all the components of the fiber, namely the core, cladding, and the jacket. The true diameter of the fiber is not always reported by the manufacturer but can be easily calculated using a hand held micrometer. For example, the measured total diameter of a Lumenis Slimline 365 fiber is 520 μm and the InnovaQuartz 400 (AMS, Minnetonka, MN) fiber is 718.5 μm, both significantly greater than their core diameters. The total fiber diameter is an important factor in determining the flow rate through the channel of a flexible ureteroscope, as most flexible ureteroscopes have only one working channel that is shared for both irrigation and instruments. Based on Poiseuille’s Law that flow rate is proportional to four times the power of the radius, a larger fiber results is a dramatic reduction in flow rate through the ureteroscope as compared to a smaller diameter fiber. When tested, the smaller Lumenis Slimline 365 had a flow rate of 17.2 mL through a flexible ureteroscope channel whereas the larger InnovaQuartz 400 fiber had a greater than 50% reduction in flow measured at 7.7 mL/s [13]. Similarly, when fibers with ≤272 μm core sizes were measured, the fibers diameters varied greatly amongst those measured. For example, the Boston Scientific Accuflex 150 had a measured total diameter of 270 μm, while the Trimedyne FlexMAX 200 (Lake Forest, CA) had a true diameter of 445 μm [12].

Fiber Flexibility

An important aspect of fiber performance is the ability of the fiber to deflect easily so as to not limit the deflection of the ureteroscope. High fiber flexibility is essential when trying to reach stones located in the lower pole where high degrees of deflection are required [14, 15]. Furthermore, greater flexibility of the fiber will result in less strain on the deflection mechanism of delicate ureteroscopes potentially reducing costly failure.

The maximum deflection (primary and secondary active deflection) of a Stryker (Kalamazoo, MI) FlexVision U-500 ureteroscope without a laser fiber in the working channel is 275°. A series of laser fibers were placed in the working channel of the Styker ureteroscope and the loss of deflection from baseline was recorded. Fibers with the smallest diameters, such as the Boston Scientific AccuFlex 150 (measured diameter of 270 μm), resulted no loss of deflection, whereas the larger Lumenis Slimline EZ 200 (measured diameter of 423 μm) resulted in a 53° loss of deflection. When the 365 μm core sized fibers were tested, significantly greater degrees of deflection were lost. For example, the Laser Peripherals HBLF-365 (true diameter of 717 μm) a total of 97° of deflection were lost [12]. Therefore when selecting fibers to use with a flexible ureteroscope, a ≤272 μm fiber is recommended in order to maximize the flow rate and deflection, while simultaneously attempting to limit the wear and tear on the delicate ureteroscope.

Are Laser Optical Fibers Interchangeable with Different Holmium:YAG Lasers

A multitude of different holmium:YAG lasers and optical fibers are commercially available. Most laser manufacturers offer a product line of laser fibers to be used with their lasers. In addition, “fiber only” manufacturers may offer various optical fibers that are marketed to be used with various commercially available laser systems. Therefore innumerable combinations of different lasers and fibers can occur. While an exhaustive list of these combinations in beyond the scope of this chapter, it is important to note that not all combinations of holmium:YAG lasers and fibers are compatible and that incompatibilities can result in damage to both the fiber and to the laser energy source.

In an experiment where a series of laser optical fibers were tested, a catastrophic failure occurred when a Tridedyne 200 fiber was attempted to be coupled with a NewStar holmium:YAG laser. The laser energy from the NewStar laser was not effectively launched into the core of the fiber, resulting in heating and ultimately melting of the connector end of the fiber, requiring extensive repair. Similarly during clinical use, a 13% (4/30) rate of fiber failure occurred when the Trimedyne 200 fiber was coupled to a Lumenis VersaPulse 100 W laser [16]. Therefore, urologists should exercise caution when mixing and matching different brands of laser fibers with different lasers. One size does not fit all.

New Advances in Holmium:YAG Optical Laser Fibers

Both tapered and non-tapered connecters are used in commercially available sub-300 μm laser fibers. Fibers with core sizes ≤200 μm are usually tapered to more efficiently route the laser energy into the core of the fiber. Previous work has suggested that non-tapered holmium:YAG laser fibers have better overall performance and are less prone to failure that smaller tapered fibers, especially in regards to resistance to failure with bending (Fig. 14.3) [12]. The majority of non-tapered small core sized fibers used for flexible ureteroscopy and laser lithotripsy have been approximately 270 μm in diameter. More recently a new single-use 240 μm fiber has been introduced and represents a novel design. The fiber (Flexiva, Boston Scientific, Natick, MA) has a non-tapered connector and is rated to handle up to 50 W of power.